Switchmode Power Supply Operation and Design

Switchmode Power Supplies vs Linear Power Supplies

The vast majority of low voltage external power supplies sold globally these days are switching (switchmode) units, as opposed to the original Linear technology, which is only considered appropriate for certain niche markets due to it’s inability to meet required efficiency standards.

In this article we will explore just some of the technical aspects & features and benefits of Switchmode topology vs Linear.

Linear Power Supplies

Before switch mode power supplies became the norm, the dominant technology was based around an iron ‘Linear’ transformer.

Linear transformers are simple to manufacture, only requiring a ratio of turns on the output relative to the input voltage, - i.e. if you had 10 turns on the primary to every one on the secondary side, then you have a transformer that gives you one 10th of the mains voltage – so typically 24V in the UK. All that is then required are some capacitors to smooth out the ripple voltage and a regulator (if required) and you’re in business!

Because of the relatively agricultural level of technology in a Linear power supply and the low component count they are extremely robust, offering very long operational lifetimes and with a reputation for almost bulletproof reliability (indeed about the only thing than can fail in time is the capacitors drying out and causing a fluctuation in the output).

However, as one might reasonably conclude there are several significant drawbacks which resulted in Linear units being almost completely eliminated from new products being designed today. The transformer itself is a large lump of iron, so the units are very heavy...

A simple test: If you drop one on your foot and break a bone, then it’s a Linear power supply!!

The transformers are also built to operate from a fixed input voltage, so will not give the correct output if used with a different mains voltage – in the previous example if the 10:1 transformer was used in the USA with a 120V input, the output would then be 12 instead of 24, so different units are required for different markets.

However, the main reason for withdrawal of Linear units is the lack of efficiency achievable with this design, they are required to constantly draw a small mag current from the mains even with no load (and consumers always leave products plugged in and turned on) and under operation can only meet low 80s in terms of power efficiency percentages, which is insufficient even to meet the original EuP/ErP standards, let alone the latest requirements.

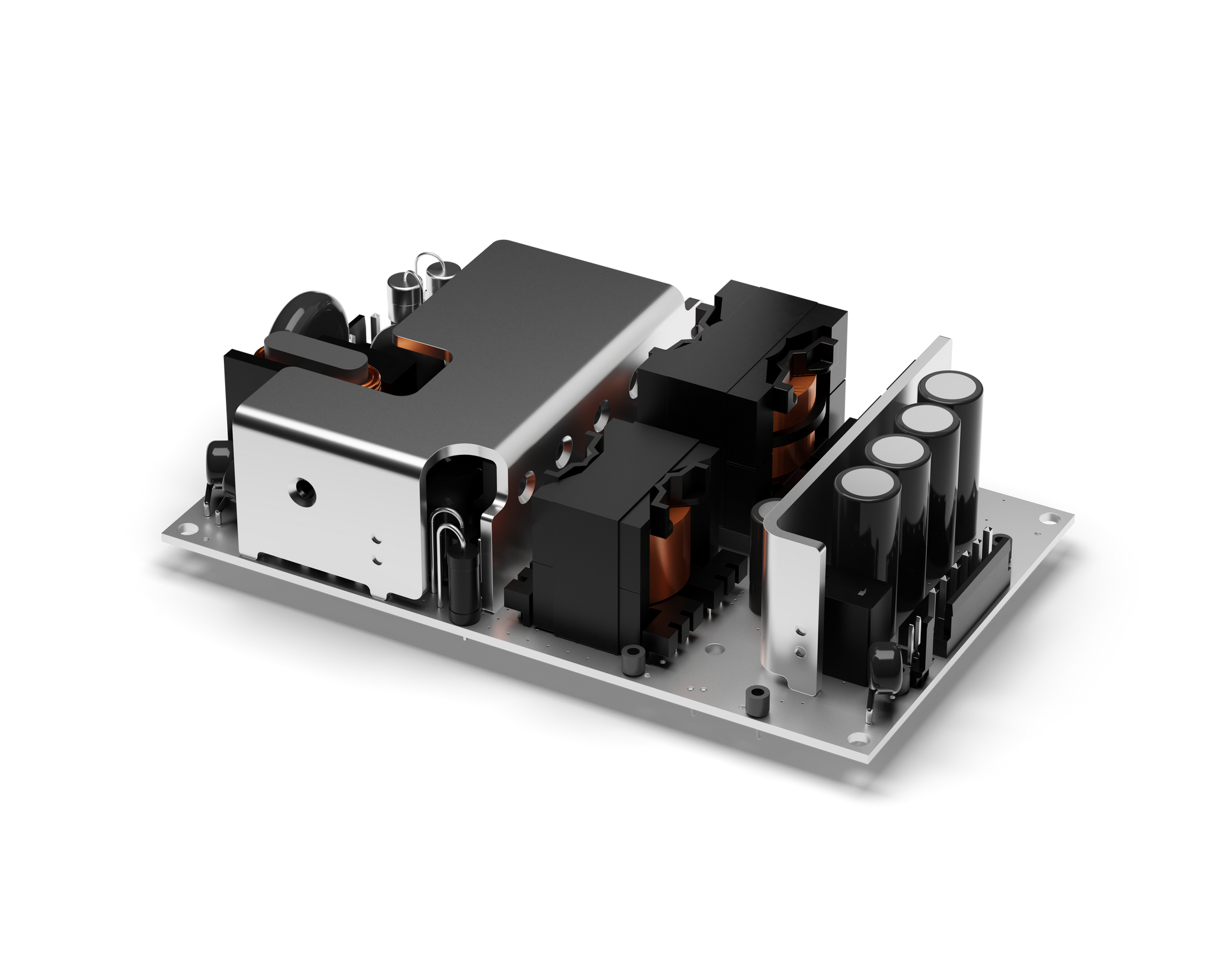

Switchmode Power Supplies

Switchmode power supplies, as the name implies, are based around a switch to control the input power to the circuit, this creates a dynamic system whereby the rate of switching can change to compensate for variations in input voltage (line regulation) or output current (load regulation) to ensure a stable output across a wide operating window. Because you are only drawing (a bit more) power than you need this design is much more efficient (although the 100% efficient product remains a fantasy of the government standard writers) and the same circuit can be used with any of the worldwide mains voltages and give the same output.

The first significant technical implication of a switch operating at a frequency of 10’s or 100’s of kHz is the noise generated, switchmode power supplies are perennially one of the noisiest parts of any design and can be relied upon to attract the attention of the test engineers when it comes to emissions compliance testing. Of course additional filters and ferrites can be added to the system to mitigate some of this noise, but this adds to the cost and reduces the efficiency, so making the design as quiet as possible in the first place is one of the key priorities of the PSU design engineer, such as FRIWO.

The other major factor for a switchmode power supply, particularly a Class II double insulated product is to maintain the safety isolation between the primary and secondary sides of the board. In order to regulate the output there has to exist a feedback circuit, and small amounts of leakage current can cross this barrier, in earthed products this can be removed but with Class II devices this has to be actively managed. Further complicating the design challenge is that a number of the methods that help to reduce the noise from a switchmode circuit, for example capacitors between the primary and secondary (Y caps) can significantly increase this potential hazard. Certain standards, most notably IEC 60601 for medical devices mandate maximum levels for leakage current for the various classifications of medical product, meaning that the use of capacitors to eliminate the noise is not really feasible.

Thus the design of a switchmode power supply is of necessity a compromise, balancing EMC, efficiency, safety and cost. One can be maximised at the expense of another, there are clever methods to produce power supplies that have good performance in all categories simultaneously, but we’re not going to go into that in this blog (it’s our secret….)

View our range of switchmode power supplies below...

Have a power requirement?

FRIWO have been making high performing power supplies for industrial and medical markets for over 50 years, and Haredata Electronics have been their UK arm for over 35, so if you have a technical challenge you need to solve, we’d be delighted to let you know how we can help.

CONTACT US