USB Type-C Chargers VS Micro USB Chargers

The micro USB connector has been the most common connector for plug top devices for the last few years, but as with everything the times are changing.

This is where the Type-C USB has started to step in, with more and more pieces of tech coming with a Type-C charger rather than the old favourite.

So the question is why?

If the old micro USB isn’t broken then why ‘fix’ it?

A brief history of the USB

The Universal Serial Bus (or USB to you and me) was developed back in the 1990's as a way to standardise and unify cables between different devices so that data and power could be transferred with ease and through the same connection.

Do you remember having a different charger and cable for each device?!

The micro USB was simple, compact and for this reason became the industry standard, especially for consumer electronics, this connection was being used by leading companies all around the world (except for that one doctor repulsing electronics company, but we won’t go there!)

So what advantage does using a different USB type have?

Advantages of the Type-C USB

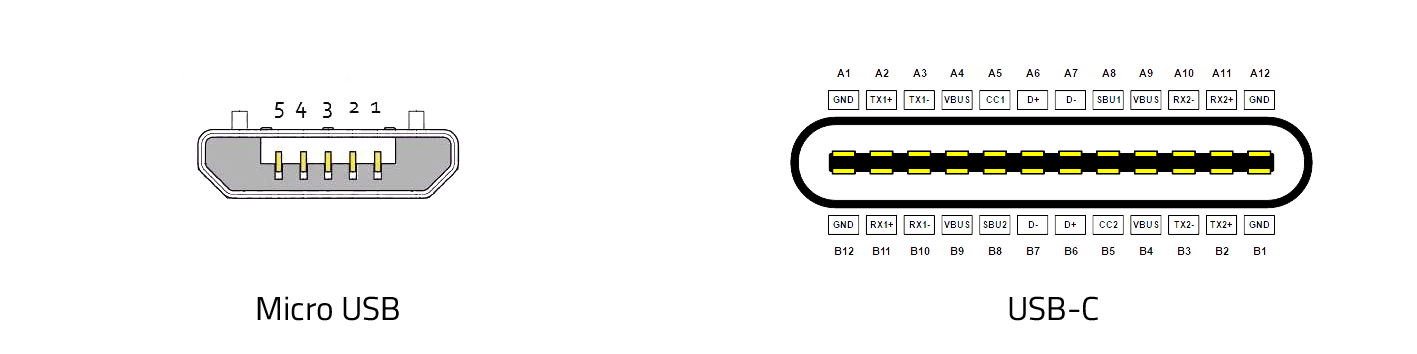

When you first look at the Type-C the first thing you will notice is the larger and slightly rounder profile but that’s not the biggest difference, beneath the surface there’s so much more to it!

The shape of the USB-C is of benefit to the user, unlike the micro USB the Type-C can’t be placed in the wrong way making it more user friendly and helping to prevent damage to the connector or socket (it’s not easy to try and force a Micro USB in ‘upside down’ but that doesn’t stop some people trying!)

This new standard also takes advantage of USB 3.0/3.1 data transfer speeds and a higher capability ensuring fast charging and transfers of data.

The USB itself can deliver up to 100W of power, enough to power laptops and other larger devices, which mean you are no longer tied to 5V.

The USB-C has been designed for a one size fits all approach able to replace connector cables in a range of technology such as phones, laptops, cameras. The versatility and power of the USB-C allows it to eventually replace all type a ports meaning that double ended connector cables will become the norm soon enough.

How USB Type-C is wired

As you can see from the above diagram there is far more connections on the Type-C vs the Micro USB.

This allows the cable to achieve much more than its predecessor, such as device recognition, faster data transfer speeds and the connector interface can also support display in/out supporting resolutions up to 4K, which means you don’t need HDMI or VGA!

As a power supply company what we are most interested in is the power delivery, which brings us nicely onto the next section...

USB-C Power delivery

USB or plug-in power supplies will typically only utilise 2 pins, a positive (V) and negative (GND).

A power supply with a Micro USB connection will deliver what is expected from it, however a USB-C device may not be as straight forward!

As seen in 'Figure 3' the USB Type-C cable and socket each have a CC1 and a CC2 pin.

Resistors of different values can be attached to these pins in various configurations depending upon the requirement.

The attached resistors allow the CC pins to perform the following functions:

- Detection of cable attachment

- Detect the orientation of the attached cable

- Advertisement of the power capabilities of the attached cable

So how much power can be supplied with different resistors?

| 56 kΩ | USB 2.0 Default, 500 mA @ 5V |

|---|---|

| 56 kΩ | USB 3.0 Default, 900 mA @ 5V |

| 22 kΩ | 1500mA @ 5V |

| 10 kΩ | 3000mA @ 5V |

Additionally, shorting the data pins (D+ & D-) signals to the client device (the one being powered) that it can draw more current if it wants it.

This is most common for 5V 3000mA applications.

USB Socket VS Fixed lead USB-C Power Supplies

You may have clicked on this blog if you are looking to source a USB Type-C Power Supply for your application, we can help with that!

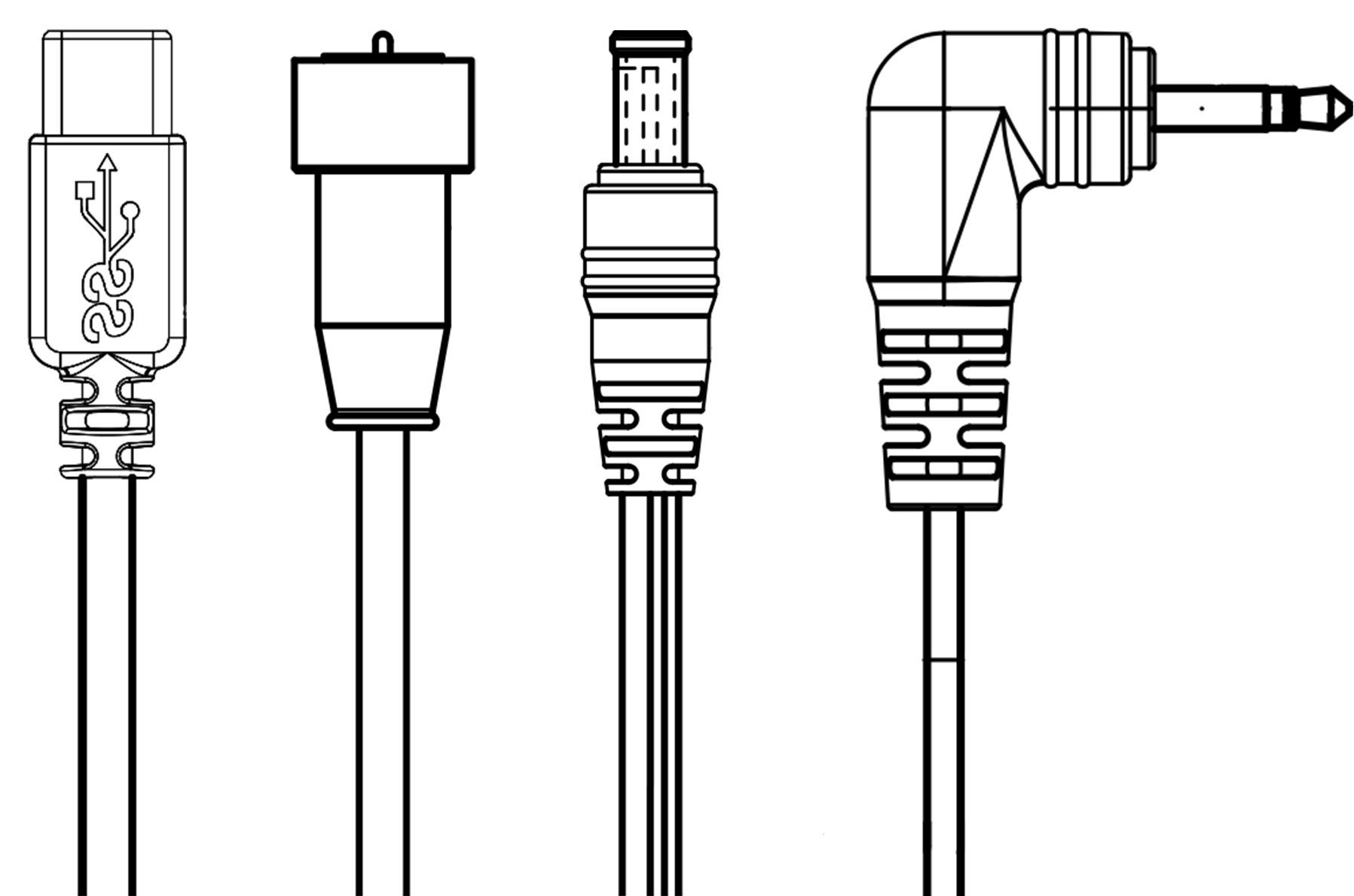

When designing a USB powered application, choosing the right adaptor with the correct power, connector and cable is key to using the power supply to its best capabilities. The options available when pairing a USB Type-C cable to a power supply are a USB socket with Type-A to C cable or a fixed lead product where the output cable is moulded to the power supply.

Choosing a USB socket PSU has advantages; it can be packaged more easily and can be interchanged a range of cables for other applications, but this is also it’s downfall, for example, a 5V 2000mA power supply requires a cable with a 10kΩ resistor to deliver it’s full charge current, however the end customer could misplace the original cable and use a different USB-C cable fitted with a 56kΩ resistor, this would limit the power delivery by half!

Moreover, most consumers would have no idea the ‘issue’ with their product was as a result of using a different cable.

As a result, we always recommend using a fixed lead product if possible, this eliminates the risk of the client using an inferior cable so you can be sure your application is supplied with the intended power.

To further pair our power supplies with your application we can brand the PSU with your logo, description or part number you require. This has the additional benefit of easily identifying the power supply as belonging to the OEM device, just in case someone needed to ‘borrow’ it to charge their mobile phone.

CONTACT US